Geogrids have received considerable attention in civil engineering for their essential role in reinforcing soil in various applications, from road construction to retaining walls. Among the various types of geogrids available, Uniaxial geogrid in India is particularly valued for its robust performance in applications where load distribution and stability are critical. As the demand for such innovative solutions grows, it becomes imperative for contractors, construction engineers, and project managers to understand how to install uniaxial geogrids properly. This article explores time-tested techniques for effective installation, providing insights for industry professionals.

Understanding Uniaxial Geogrid

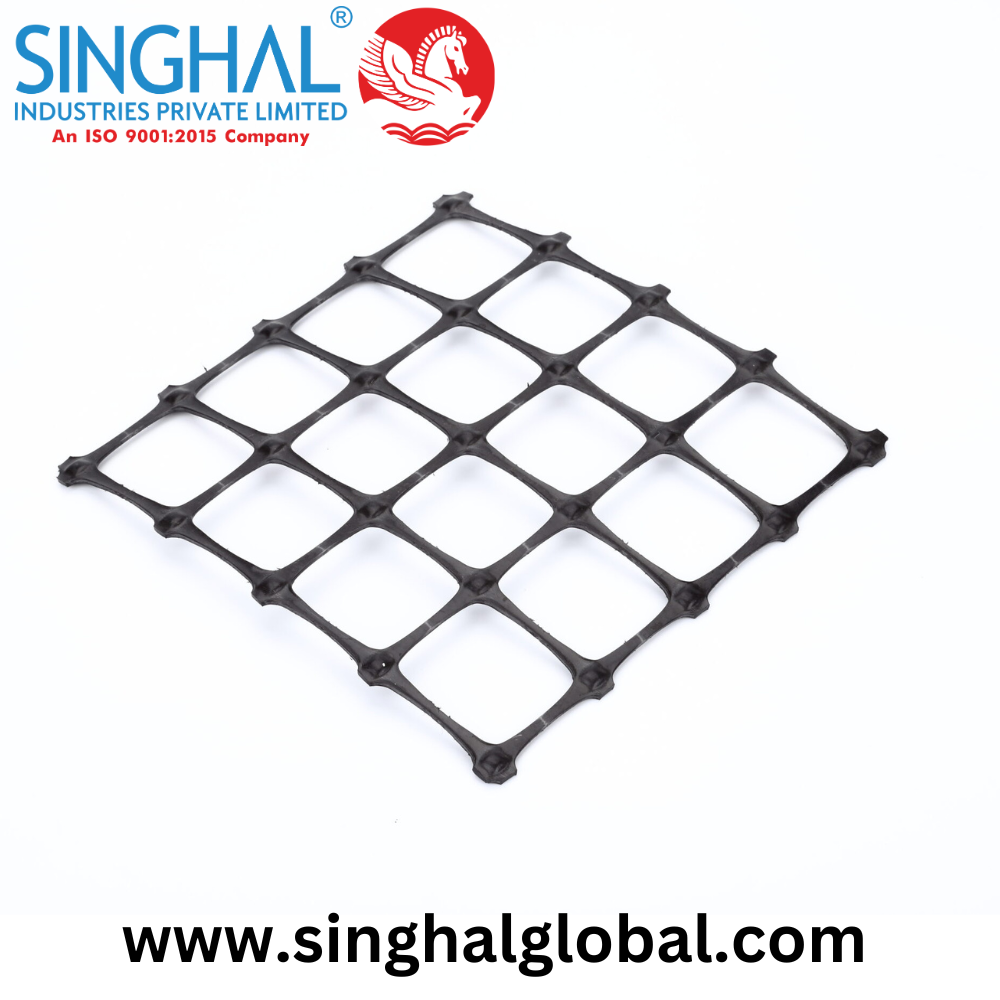

Before delving into installation techniques, it’s crucial to comprehend what uniaxial geogrids are and why they are indispensable in modern construction. The geogrids are made from high-strength polymer materials, designed with a series of openings that allow the reinforcement of soil and aggregate structures. When installed correctly, uniaxial geogrids serve to enhance load-bearing capacity and minimize settlement, making them an ideal choice for applications such as:

- Reinforced slopes

- Retaining walls

- Embankments over weak soils

- Roadways and access roads

Top manufacturers and suppliers specializing in geosynthetic materials, particularly uniaxial geogrids, have established their reputations based on quality and effective performance, especially in regions like India where construction projects are on the rise.

Pre-Installation Considerations

Proper installation begins long before the geogrid is laid. The first step involves thorough site analysis and preparation. Here are some essential pre-installation considerations:

-

Soil Assessment: Before laying down the uniaxial geogrid, the soil’s type and condition must be examined. This includes assessing its compaction, moisture content, and overall stability. Proper analysis helps determine the depth and spread of the geogrid reinforcement needed.

-

Design Specifications: Each project has unique requirements based on its load, soil type, and environmental conditions. Engaging with a qualified geotechnical engineer will ensure that the correct specifications are designed, including the selection of the proper uniaxial geogrid and its installation method.

-

Selecting the Right Uniaxial Geogrid: As reputable Uniaxial geogrid manufacturers and suppliers offer various products, choose a geogrid that aligns with the project’s requirements. Pay attention to factors such as tensile strength, durability, and UV resistance.

Installation Techniques

Once pre-installation considerations are accounted for, proper installation techniques can be carried out. Here are essential steps for installing uniaxial geogrids effectively:

-

Site Preparation: Clear the area of any debris, vegetation, or loose material. The foundation should be compacted to achieve a stable base for the uniaxial geogrid installation. Any irregularities should be leveled to ensure uniformity during the application.

-

Laying the Geogrid: Unroll the geogrid carefully onto the prepared site. Avoid excessive bending or curling, which may impair the grid’s structural integrity. Lay the geogrid in the direction that will align with the expected loads, as the design is typically tailored for uniaxial loading conditions.

-

Securing the Geogrid: Depending on the application, the geogrid may need to be anchored or secured. Use appropriate anchors, staples, or stakes to hold the geogrid in place, especially on sloped surfaces, to prevent shifting during subsequent layers of material application.

-

Layering: If the project requires multiple layers, ensure each layer of material—such as aggregate or soil—is compacted before laying down the subsequent geogrid layer. Proper compaction enhances interlocking and load transfer efficiency.

-

Backfilling and Compaction: Once the geogrid has been set in place, backfilling can begin. Make sure that the backfill material is evenly distributed and adequately compacted to avoid voids and ensure optimal load distribution across the uniaxial geogrid.

-

Final Checks: After the installation, perform a thorough inspection to check for alignment, tension, and overall installation quality. Correct any discrepancies to ensure the installation meets the project’s design specifications.

Ongoing Maintenance and Evaluation

Once installed, ongoing maintenance is crucial to ensure the longevity and performance of the uniaxial geogrid reinforcements. Regular inspections and monitoring are necessary to detect erosion, movement, or any settling that may compromise the system. Proper management sustains the integrity of the structure and minimizes potential hazards.

Why Choose Uniaxial Geogrid?

Investing in uniaxial geogrids is often met with great returns in terms of performance and longevity. These materials improve overall structural strength, decrease environmental damage, and offer cost-effective solutions in the long run. Skilled Uniaxial geogrid suppliers and manufacturers ensure that quality and efficiency are retained throughout installation processes, leading to successful construction outcomes.

Conclusion

In conclusion, mastering the various techniques for installing uniaxial geogrids can make all the difference in the success of construction projects. By adhering to time-tested methods, professionals can achieve better load distribution, enhanced structural stability, and prolonged longevity of geogrid applications.

Frequently Asked Questions (FAQs)

-

What is the typical lifespan of uniaxial geogrid materials?

The lifespan of uniaxial geogrids typically ranges from 20 to 50 years, depending on environmental conditions, soil type, and the maintenance practices employed. Proper installation and regular monitoring can significantly enhance their longevity. -

How do I identify the right supplier for uniaxial geogrids in India?

To select a reliable uniaxial geogrid supplier in India, consider their reputation, product variety, quality certifications, and customer reviews. Engaging with previous clients can provide insights into their reliability and service quality. -

Can uniaxial geogrids be used in all soil types?

While uniaxial geogrids are versatile, specific soil conditions may require different applications or installation techniques. Conducting a thorough soil analysis enables the proper use of uniaxial geogrids in varying soil types to ensure optimal performance.

Leave a Reply