In the realm of manufacturing and mechanical design, one of the most important aspects of creating functional, durable, and efficient products is ensuring that the geometry of each part is well-optimized. Two fundamental geometric features often considered in product design are the chamfer vs fillet. Both serve specific purposes, but they have different characteristics, applications, and impacts on a part’s performance and manufacturability.

In this article, we’ll explore the key differences between chamfers and fillets, their functions, when to use each, and how they contribute to various engineering applications.

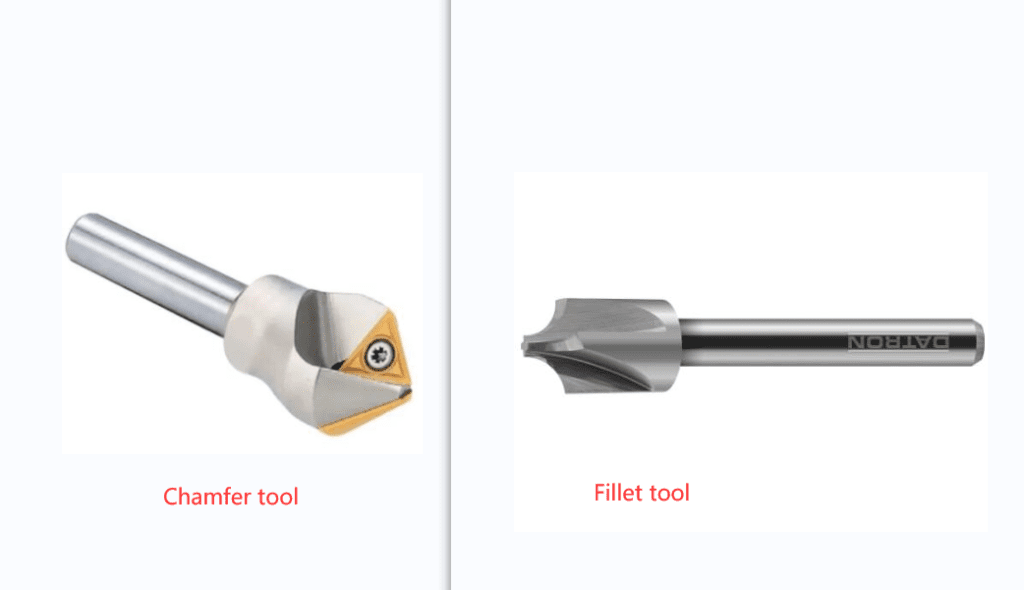

What is a Chamfer?

A chamfer is a beveled edge or corner that replaces a sharp, 90-degree angle with a slanted, flat surface. Chamfers are typically cut at a 45-degree angle but can be adjusted to other angles depending on the application. They are commonly used in various manufacturing processes, such as milling, turning, and drilling. The primary purpose of a chamfer is to eliminate sharp edges and corners, which can be hazardous or lead to damage during handling or assembly.

Characteristics of Chamfers:

- Flat, angled cut that replaces sharp corners.

- Typically a 45-degree angle, though it can be adjusted to suit the design needs.

- Can be applied to both internal and external corners.

Applications of Chamfers:

- Safety: Chamfers are often used in product design to remove sharp corners that could lead to injury or damage.

- Assembly: Chamfers can facilitate easier part assembly by guiding components into place and reducing friction during fitting.

- Cosmetic Finishes: Chamfers are commonly used for aesthetic reasons, adding a sleek, professional appearance to parts by smoothing out sharp edges.

- Deburring: After the manufacturing process, chamfers are used to remove burrs or remnants from cutting, creating a cleaner edge.

Benefits of Chamfers:

- Improved Safety: By removing sharp edges, chamfers reduce the risk of injury during handling and assembly.

- Enhanced Appearance: Chamfers can improve the overall visual appeal of a part, providing a polished, modern finish.

- Simplified Manufacturing: Chamfers are relatively simple and cost-effective to create using conventional machining methods.

What is a Fillet?

A fillet is a rounded corner or edge that replaces a sharp corner with a smooth curve. Fillets are used to connect two surfaces or edges and are typically used to reduce stress concentrations in critical areas of a part. By providing a gradual transition between surfaces, fillets improve the flow of forces across the part, helping to enhance its strength and reduce the likelihood of failure under stress.

Characteristics of Fillets:

- Curved transition between two intersecting surfaces or edges.

- Typically concave (curved inward), although convex (curved outward) fillets can also be applied.

- Radius can vary based on the application, allowing for precise control over stress distribution.

Applications of Fillets:

- Stress Relief: Fillets are often applied in areas of high stress, such as in structural components, to help distribute stress more evenly and prevent fractures.

- Fluid Flow: In piping systems or aerodynamics, fillets can help improve the smoothness of fluid or air flow by reducing turbulence at corners.

- Strength Improvement: By reducing sharp corners, fillets can improve a part’s fatigue resistance, making it more durable over time.

- Welding: Fillets are often used in welding applications to create smooth, strong weld joints between two pieces of metal.

Benefits of Fillets:

- Reduced Stress Concentration: Fillets help to evenly distribute forces, reducing the chance of cracks or failure at corners, especially in high-stress applications.

- Enhanced Durability: Fillets improve the structural integrity of a part, increasing its resistance to fatigue and mechanical failure.

- Better Flow: In systems where fluid or gases are involved, fillets provide a smooth transition, enhancing the efficiency of the flow.

Chamfer vs Fillet: The Key Differences

While chamfers and fillets are both used to modify edges and corners, they differ significantly in their geometry, functionality, and the impact they have on the part’s design and manufacturing. Below is a comparison of the two:

1. Shape and Geometry

- Chamfer: A chamfer is a flat, straight cut that typically occurs at a 45-degree angle, though other angles can be used depending on the application. It creates a beveled edge or corner.

- Fillet: A fillet is a smooth, rounded transition between two surfaces. It typically features a concave curve, but in some cases, it may be convex.

2. Primary Function

- Chamfer: The primary purpose of a chamfer is to remove sharp edges, facilitate assembly, improve aesthetic appearance, and help with part fitting.

- Fillet: Fillets are mainly used to reduce stress concentrations, enhance structural integrity, and improve fluid flow by smoothing the transition between surfaces.

3. Stress Distribution

- Chamfer: Chamfers do not significantly affect stress distribution. While they help eliminate sharp corners, they are not as effective at preventing stress concentration in high-stress areas as fillets.

- Fillet: Fillets play a critical role in reducing stress concentrations. The smooth, curved transition helps to evenly distribute stress and prevent cracking or fatigue at corners, which is especially important in parts subjected to high mechanical loads.

4. Manufacturing Considerations

- Chamfer: Chamfers are generally easy and inexpensive to manufacture. They can be produced using standard machining techniques, such as milling or turning, and don’t require complex equipment or additional processes.

- Fillet: Fillets, especially in certain applications like casting or welding, may require more advanced manufacturing techniques and specialized equipment. Creating a precise fillet can be more time-consuming and costly compared to chamfers, depending on the geometry of the part.

5. Cost Efficiency

- Chamfer: Chamfers are typically more cost-effective and quicker to produce, making them ideal for high-volume manufacturing where cost and time efficiency are key considerations.

- Fillet: Fillets may incur higher costs, especially for parts requiring intricate or large-radius fillets. The additional time and resources needed to create a smooth curve often result in a higher manufacturing cost.

When to Use Chamfer vs Fillet

Choosing between a chamfer and a fillet depends largely on the intended function of the part, its mechanical requirements, and the specific design goals. Below are guidelines on when to use each feature:

When to Use a Chamfer:

- For Deburring: Chamfers are ideal for removing sharp edges and burrs from parts after machining.

- For Ease of Assembly: Parts that need to fit together with minimal friction or difficulty benefit from chamfers, which guide components into place.

- For Aesthetics: When a clean, modern appearance is desired, chamfers can be used to create smooth, beveled edges that improve the visual appeal of the product.

- For Cost-Effective Design: Chamfers are ideal for simple parts where high stress resistance is not a primary concern, making them suitable for large-scale production runs.

When to Use a Fillet:

- For Stress Relief: When designing parts that will experience high stress or fatigue, fillets help to evenly distribute the stress and prevent failure.

- For Improving Flow: In piping systems, fluid dynamics, or aerodynamics, fillets are used to ensure smoother transitions and reduce turbulence at corners.

- For Strengthening: Fillets enhance the structural strength of parts, making them better suited to withstand repetitive mechanical forces and prolonged use.

- For Welding Joints: In welded parts, fillets provide strong, smooth transitions that prevent weakness at the corners, helping to improve the joint’s overall integrity.

Conclusion

Both chamfers and fillets are essential tools in the design and manufacturing world, each serving a distinct purpose. Chamfers are ideal for simplifying part assembly, enhancing safety, and providing aesthetic finishes, while fillets are crucial for stress relief, improving structural integrity, and optimizing fluid flow.

Understanding the differences between chamfers and fillets and knowing when to apply each feature is vital for creating high-performing, durable parts. Whether designing for high-stress applications or aiming for visual appeal, these geometric features play a crucial role in the overall success of a product’s design and functionality.

Leave a Reply