Polypropylene (PP) sheets have become an essential material in many industries, owing to their versatile properties, durability, and ease of processing. From manufacturing to construction, PP sheets are used in a variety of applications, ranging from packaging to insulation and even medical equipment. However, to maximize their potential, it’s important to know how to cut and shape these sheets effectively.

In this ultimate guide, we’ll walk you through the processes of cutting and shaping by Polypropylene sheets exporters in Ahmedabad, explore the best methods, tools, and techniques, and highlight important factors to consider. Whether you are a manufacturer, a craftsman, or just someone who frequently works with PP sheets, this guide will provide you with the knowledge you need to get the job done right.

Understanding Polypropylene Sheets

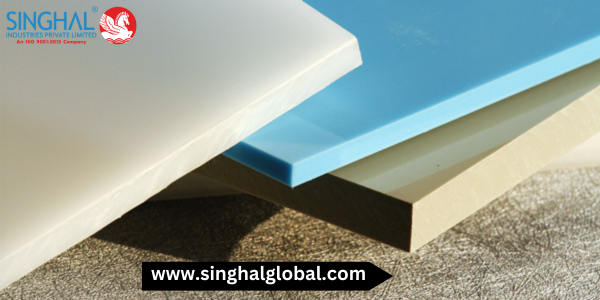

Polypropylene is a thermoplastic polymer, which means it becomes soft and moldable when heated and hardens once it cools. This characteristic makes PP sheets incredibly easy to shape and form into different designs, especially when using the proper cutting techniques. PP sheets are available in a variety of thicknesses, colors, and finishes, making them suitable for a broad range of uses.

The material is popular due to its exceptional chemical resistance, impact strength, and relatively low cost. These sheets are lightweight, non-toxic, and weather-resistant, which makes them highly versatile for both indoor and outdoor use.

Cutting PP Sheets: Methods and Tools

Cutting PP sheets can be done using a variety of methods, depending on the thickness of the material, the precision required, and the equipment available. Below are the most common cutting techniques for PP sheets:

1. Using a Utility Knife

For thin PP sheets (typically up to 3mm thick), a utility knife can be a simple and effective tool. When using a utility knife, ensure that the blade is sharp to avoid jagged edges or uneven cuts. Here’s how to do it:

- Mark the desired cutting line on the sheet using a pencil or marker.

- Score the sheet along the line with the utility knife.

- Place the sheet on a cutting surface, ensuring that the scored line is hanging over the edge.

- Apply pressure to break the sheet along the scored line.

This method is best for cutting straight lines, but it can also be used for smaller, intricate cuts if done carefully.

2. Circular Saw

For thicker PP sheets (above 3mm), a circular saw equipped with a fine-toothed blade can deliver precise cuts with ease. Follow these steps for optimal results:

- Secure the PP sheet to a stable work surface using clamps.

- Set the saw depth to match the thickness of the material.

- Guide the saw along the marked line, keeping it steady to prevent any rough edges or unnecessary strain on the material.

Circular saws are excellent for cutting large quantities of PP sheets quickly and efficiently, especially when working with sheets that are 5mm or thicker.

3. Jigsaw

Jigsaws are useful for making intricate cuts and curves in PP sheets. To use a jigsaw effectively:

- Mark the cut lines on the PP sheet.

- Attach a fine-toothed blade suitable for plastic to the jigsaw.

- Slowly guide the jigsaw along the marked path, ensuring to keep the sheet stable and preventing it from shifting.

Jigsaws are ideal for cutting complex shapes and curves in PP sheets, allowing for a higher level of precision.

4. Laser Cutting

Laser cutting offers one of the most precise methods for cutting PP sheets. It uses a focused laser beam to vaporize the material along the cutting line. This process can create clean, smooth cuts without the need for post-processing. However, laser cutting equipment can be expensive and may not be suitable for smaller-scale operations.

Laser cutting works best for both thin and thick PP sheets and is particularly beneficial for creating detailed designs, such as logos or custom shapes.

5. CNC Router

A CNC router is a computer-controlled cutting machine that can automate the cutting process for PP sheets. It can be programmed to make precise, repeatable cuts, whether straight or curved, and is ideal for large production runs. CNC routers are highly efficient for creating complex shapes, including slots, holes, and patterns, with minimal effort.

Shaping PP Sheets: Techniques and Tools

In addition to cutting, shaping PP sheets is another crucial aspect of utilizing this versatile material. Shaping involves bending, folding, or molding the material into different forms based on specific project needs. Below are some of the most effective methods for shaping PP sheets:

1. Heat Bending

Heat bending involves applying heat to the PP sheet at the point of bending to soften it, making it easier to form. Here’s how you can do it:

- Place the PP sheet on a flat surface and mark the area where the bend will occur.

- Use a heat gun or oven to heat the sheet to approximately 150°C (302°F), until the material becomes flexible.

- Once heated, gently bend the sheet to the desired angle or shape.

- Allow the sheet to cool, and the shape will harden.

Heat bending is commonly used to create sharp or curved edges on PP sheets, especially for product enclosures or boxes.

2. Vacuum Forming

Vacuum forming is a process where a heated PP sheet is placed over a mold, and a vacuum is applied to pull the sheet tightly around the mold’s contours. This process is ideal for creating three-dimensional shapes, such as packaging trays or protective covers.

3. Injection Molding

For more complex shapes, injection molding is a popular technique. In this process, PP pellets are melted and injected into a mold under high pressure, where they take the shape of the mold. While it’s more commonly used in large-scale manufacturing, it’s an efficient way to produce highly customized and consistent shapes.

Choosing PP Sheet Exporters and Suppliers

When sourcing PP sheets for your business or projects, it’s crucial to find reliable suppliers and exporters. In India, there are many reputable polypropylene sheet suppliers that provide high-quality products at competitive prices. Some of the well-known PP sheet exporters in India and Polypropylene sheet suppliers in India include those based in key manufacturing hubs such as Ahmedabad. Polypropylene sheets exporters in Ahmedabad are renowned for their strong industry experience and commitment to quality, making them an excellent choice for large orders or specialized needs.

Conclusion

Cutting and shaping PP sheets is a straightforward process with the right tools and techniques. Whether you’re using a utility knife for thin sheets or a circular saw for thicker ones, there are many methods to suit your needs. Similarly, shaping PP sheets with techniques such as heat bending or vacuum forming provides the flexibility to create a wide variety of custom designs. When sourcing your materials, consider reaching out to PP sheet exporters in India or polypropylene sheet suppliers in India for high-quality products that meet your project specifications. With these tools and tips in hand, you can successfully cut, shape, and form PP sheets to bring your creative or industrial visions to life.

Frequently Asked Questions (FAQ)

-

What is the best way to prevent warping when cutting PP sheets? To prevent warping, always support the entire sheet when cutting and use a saw with a fine tooth blade. Make sure the sheet is clamped securely to a flat surface to avoid any movement during the cut.

-

Can PP sheets be welded together? Yes, PP sheets can be welded using techniques such as hot gas welding or ultrasonic welding. These methods create a strong bond between sheets, making them ideal for large-scale projects.

-

What are the key advantages of using PP sheets over other plastics? PP sheets offer exceptional chemical resistance, are lightweight, durable, and cost-effective. They are also non-toxic and recyclable, making them an eco-friendly alternative for many applications.

Leave a Reply