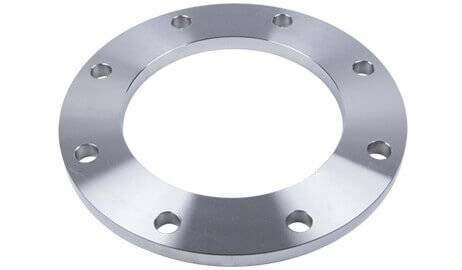

Stainless steel (SS) 316Ti flanges are a popular choice in industries requiring durable and corrosion-resistant solutions. These flanges are known for their excellent performance in extreme environments, making them indispensable in many industrial applications.

In this blog, we will delve into the benefits, types, and diverse applications of SS 316Ti flanges, offering insights into why they are a superior choice for critical piping systems.

What Makes SS 316Ti Flanges Unique?

SS 316Ti flanges are manufactured using stainless steel alloy 316Ti, a titanium-stabilized variant of the 316-grade stainless steel. Titanium in the alloy prevents carbide precipitation during welding, making the material resistant to intergranular corrosion. This stability enhances the performance of these flanges in high-temperature environments.

Key Benefits of SS 316Ti Flanges

-

High Corrosion Resistance

SS 316Ti flanges offer superior resistance to pitting and crevice corrosion, particularly in chloride-rich and acidic environments. -

Excellent Heat Resistance

These flanges can endure temperatures up to 600°C without compromising structural integrity. -

Durability

The robust mechanical properties ensure a longer lifespan even in the most challenging industrial conditions. -

Hygienic Properties

The smooth surface finish of SS 316Ti flanges makes them suitable for industries like food processing and pharmaceuticals. -

Low Maintenance

Their corrosion resistance and durability reduce the need for frequent repairs or replacements, ensuring cost savings.

Types of SS 316Ti Flanges

SS 316Ti flanges come in various designs to suit different industrial needs:

-

Weld Neck Flanges

Perfect for high-pressure applications, they provide a strong and leak-proof connection. -

Slip-On Flanges

Easy to install, these flanges are ideal for low-pressure environments. -

Socket Weld Flanges

Commonly used for small-diameter pipes, they ensure a secure connection. -

Blind Flanges

Used to seal the ends of pipelines, blind flanges are essential for maintenance. -

Threaded Flanges

These flanges are suitable for non-welded connections, making them easy to install and remove. -

Lap Joint Flanges

Frequently dismantled piping systems benefit from these flanges due to their flexibility and ease of use.

Applications of SS 316Ti Flanges

SS 316Ti flanges are widely used across industries that demand high performance and reliability:

-

Chemical Processing

Their corrosion resistance makes them ideal for handling aggressive chemicals and acids. -

Oil and Gas

These flanges are critical in pipelines, refineries, and offshore platforms due to their durability and strength. -

Food and Beverage

The hygienic properties of SS 316Ti make it suitable for food production and processing facilities. -

Pharmaceutical Industry

These flanges are used in sterile and non-reactive environments to meet stringent quality standards. -

Marine Applications

With excellent resistance to saltwater corrosion, SS 316Ti flanges are ideal for shipbuilding and marine equipment. -

Power Plants

High-temperature resistance makes them suitable for boilers, heat exchangers, and other critical systems.

Why Choose SS 316Ti Flanges Over Standard Flanges?

-

Improved Performance

Compared to standard stainless steel flanges, SS 316Ti flanges provide better performance in high-temperature and corrosive conditions. -

Enhanced Safety

Their superior strength ensures reliability, minimizing the risk of system failures. -

Cost-Effectiveness

While the initial cost may be higher, the durability and low maintenance requirements make them a cost-effective choice. -

Versatile Applications

Their adaptability to various industries and environments adds to their value.

How to Choose the Right SS 316Ti Flange?

-

Understand Your Requirements

Consider the operating temperature, pressure, and type of media involved in your system. -

Select the Right Type

Choose the flange type (weld neck, slip-on, etc.) that suits your piping configuration and application. -

Check Standards and Certifications

Ensure the flanges meet industry standards like ANSI, ASME, or DIN for quality assurance. -

Evaluate Supplier Credibility

Partner with reliable manufacturers or suppliers for high-quality SS 316Ti flanges.

Maintenance Tips for SS 316Ti Flanges

To ensure the longevity of your SS 316Ti flanges, follow these maintenance tips:

-

Routine Inspections

Regularly check for signs of wear, corrosion, or damage to prevent costly repairs. -

Proper Cleaning

Use non-abrasive cleaning solutions to remove contaminants without harming the surface. -

Preventive Coatings

Apply protective coatings to enhance resistance against aggressive chemicals or moisture. -

Correct Installation

Ensure proper alignment and tightening during installation to avoid leaks or failures.

Industries Benefiting from SS 316Ti Flanges

-

Petrochemical and Refineries

Their ability to withstand harsh chemicals and high temperatures makes them indispensable. -

Construction and Infrastructure

The durability and strength of SS 316Ti flanges make them a reliable choice for structural applications. -

Water Treatment Plants

These flanges can handle the corrosive nature of water treatment chemicals effectively.

Conclusion

SS 316Ti flanges are a premium solution for industries requiring high-performance, durable, and corrosion-resistant components. Their unique properties, including titanium stabilization and high-temperature resistance, set them apart from standard stainless steel flanges.

From chemical processing to marine environments, SS 316Ti flanges provide unmatched reliability and efficiency. By choosing the right type and maintaining them properly, you can ensure optimal performance and longevity for your piping systems.

Leave a Reply