Laser marking machines have revolutionized the engraving and marking industries, offering businesses precise, high-speed, and efficient solutions for permanent markings on a wide variety of materials. Whether you’re involved in industrial manufacturing, medical device marking, or personalization services, laser marking machines provide unmatched accuracy and versatility. One of the leading products in this field is the Lumitool Optical Fiber Laser Marking Machine, known for its advanced capabilities and exceptional performance. In this article, we will explore how laser marking machines are transforming various industries and why the Lumitool Optical Fiber Laser Marking Machine is a top choice for businesses worldwide.

What Is a Laser Marking Machine?

A laser marking machine is a tool that uses laser technology to etch or mark materials. It works by focusing a high-intensity laser beam onto the surface of the material, causing it to either vaporize or undergo a chemical reaction that produces a permanent mark. These machines are used for a wide range of applications, including engraving logos, serial numbers, barcodes, QR codes, and even intricate designs on materials like metal, plastic, ceramic, and glass.

Laser marking machines are particularly effective for creating high-contrast, durable marks that are resistant to wear, corrosion, and fading. Unlike traditional engraving methods, laser marking does not involve direct contact with the material, reducing the risk of damage and ensuring precise results.

Advantages of Using a Laser Marking Machine:

-

Precision and Detail: Laser marking machines are known for their exceptional precision. The laser beam can be focused to a very fine point, allowing businesses to create intricate, detailed designs with high clarity. Whether you’re marking a small part or engraving complex logos, a laser marking machine provides the accuracy required to deliver outstanding results every time.

-

Speed and Efficiency: Laser marking machines can operate at high speeds, enabling businesses to complete large volumes of work in less time. The ability to mark materials quickly without compromising quality is a major advantage for industries that require high production rates. For example, in the automotive and electronics industries, fast and efficient laser marking is essential for meeting tight deadlines and production schedules.

-

Versatility Across Materials: One of the standout features of laser marking machines is their ability to work with a wide variety of materials. From metals like steel, aluminum, and brass to plastics, ceramics, and even wood, laser marking machines can be used on almost any material. This versatility makes them suitable for a broad range of applications, including industrial manufacturing, product customization, and promotional goods.

-

Permanent and Durable Marks: The marks created by laser marking machines are permanent and highly resistant to fading, scratching, and environmental wear. This durability is especially important for industries that require long-lasting identification and traceability, such as aerospace, automotive, and medical device manufacturing. Laser marking ensures that the engravings remain intact even under harsh conditions, making it ideal for parts that undergo wear and tear.

-

Low Maintenance and Cost-Effective: Laser marking machines are known for their low maintenance requirements. Unlike traditional engraving tools that require regular repairs and replacements, laser marking systems typically have a long operational life with minimal upkeep. The lack of consumables, such as ink or chemicals, also makes laser marking a cost-effective solution over time. The Lumitool Optical Fiber Laser Marking Machine, for instance, provides reliable performance with minimal operational costs.

-

Environmentally Friendly: Laser marking is an eco-friendly process, as it does not generate toxic waste or require hazardous chemicals. The technology uses only a laser beam to mark materials, resulting in a clean, safe operation. This makes laser marking machines a sustainable option for businesses looking to reduce their environmental impact.

Applications of Laser Marking Machines:

-

Industrial Manufacturing: Laser marking machines are widely used in the industrial sector for marking parts and components. From serial numbers and barcodes to company logos and quality control marks, laser marking ensures that every piece is clearly identified and traceable. Industries such as automotive, aerospace, and electronics rely heavily on laser marking for efficient production and inventory management.

-

Medical Device Marking: In the medical industry, the need for precise and permanent markings is critical. Laser marking machines are used to mark surgical instruments, implants, and medical devices with serial numbers, logos, and regulatory codes. These markings are durable and resistant to sterilization processes, ensuring compliance with industry standards.

-

Jewelry and Fashion: Laser marking machines are also used in the jewelry industry for engraving intricate designs, names, and dates on rings, bracelets, and other pieces. The fine precision of the laser allows jewelers to add detailed personalizations, creating unique and one-of-a-kind pieces for customers.

-

Product Customization and Personalization: As consumer demand for customized products continues to rise, laser marking machines are a valuable tool for businesses offering personalization services. Whether it’s engraving names on gifts, adding logos to promotional items, or creating personalized home decor, laser marking offers an efficient and high-quality way to meet customer demands for customization.

-

Electronics Marking: Laser marking is essential in the electronics industry, where parts need to be labeled with part numbers, manufacturer details, and safety certifications. Fiber laser marking machines, like the Lumitool Optical Fiber Laser Marking Machine, provide the speed and precision necessary for marking small components and ensuring the traceability of electronic products.

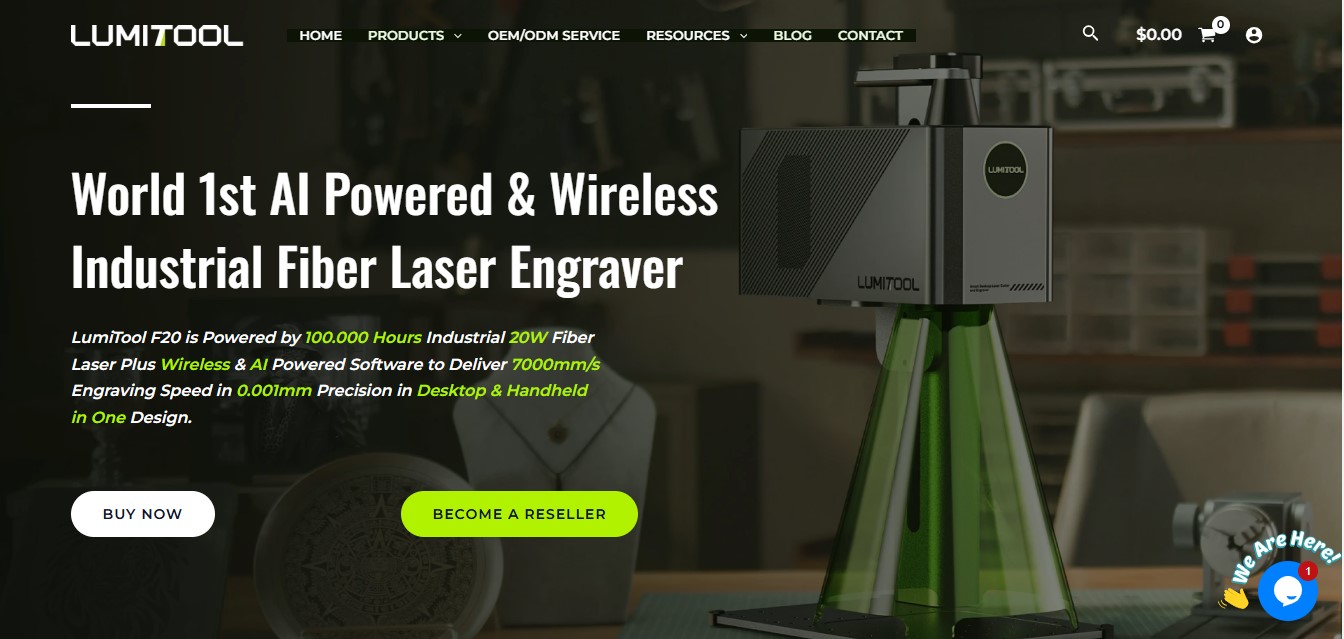

Lumitool Optical Fiber Laser Marking Machine:

The Lumitool Optical Fiber Laser Marking Machine is a top-tier solution for businesses looking to enhance their marking and engraving capabilities. With its advanced fiber laser technology, this machine offers superior performance, high precision, and the ability to mark a wide range of materials. Its user-friendly interface, along with its robust build quality, ensures long-term reliability and ease of operation.

This machine is particularly ideal for industries that require intricate and permanent markings, such as automotive, electronics, and medical device manufacturing. Its versatility and ability to handle a range of materials make it an excellent investment for businesses that want to expand their production capabilities while maintaining high-quality standards.

Conclusion:

Laser marking machines are an essential tool for modern businesses, offering unmatched precision, efficiency, and versatility. With applications spanning various industries, from industrial manufacturing to jewelry engraving and medical device marking, these machines provide solutions for businesses looking to stay competitive in a fast-paced market. The Lumitool Optical Fiber Laser Marking Machine stands out as a reliable and efficient choice for companies that require high-performance laser marking solutions. By investing in a laser marking machine, businesses can increase productivity, reduce operational costs, and deliver superior-quality marks that will stand the test of time.

Leave a Reply